Blogs

AI in Manufacturing: Enhance Efficiency, Precision, Innovate!

Manufacturing is currently experiencing a transformative AI revolution, which has the potential to unlock an impressive $3.5 trillion in annual value. Manufacturers are increasingly adopting AI technologies to enhance operational efficiency, improve product quality, and drive significant advancements across the industry.

As we progress into the era of Industry 4.0, AI is reshaping every facet of manufacturing, from the shop floor to supply chain management, predictive maintenance, and product innovation. The integration of AI technologies allows manufacturers to achieve unprecedented levels of productivity, quality, and customization.

This blog series delves deeply into the extensive and varied applications of AI in the manufacturing sector, highlighting its transformative potential. We explore how AI technologies can streamline operations, enhance product quality, and drive innovation. By examining case studies and real-world implementations, we demonstrate how AI can significantly boost operational efficiency, reduce costs, and ultimately deliver substantial business value.

This blog explores the multifaceted applications of AI in manufacturing and highlights its role in enhancing efficiency, improving quality, and driving innovation, we explore how AI transforms manufacturing at different levels.

In the following sections, we will delve into the specific ways AI is being deployed across the manufacturing value chain, from machine vision and robotics to advanced analytics and decision support systems:

- Machine Vision and Robotics: AI-powered machine vision systems inspect electronic components for defects during assembly, ensuring precision and consistency. AI-driven robots adapt to various tasks, such as soldering and component placement, enhancing flexibility and precision. This system significantly improves the quality and speed of the assembly process, reducing the likelihood of defects and rework.

- Embedded AI in Products: AI-embedded HVAC units autonomously monitor and report performance metrics, adjusting settings in real-time to optimize energy usage and indoor climate. This leads to highly responsive and efficient building management, reducing energy costs and improving occupant comfort through continuous performance monitoring and adjustment.

- Machine Learning and Knowledge Discovery: Advanced AI algorithms analyze extensive datasets generated during pharmaceutical production, including unstructured data from lab reports and production logs. These algorithms uncover patterns critical for predictive maintenance, process optimization, and quality control. The insights are also used to create digital twins of production lines, enhancing operational efficiency and reliability.

- AI Forecasting and Prediction: AI models analyze historical sales data, market trends, and consumer behavior to forecast future demand for apparel products with high accuracy. This optimizes inventory management, reducing overstock and stockouts, and minimizes waste, ensuring that production aligns closely with market demand.

- AI Diagnosis and Maintenance: AI-driven diagnostic tools continuously monitor the health of aerospace manufacturing equipment, predicting potential failures and scheduling maintenance before issues occur. This minimizes downtime, reduces maintenance costs, and ensures the continuous operation of critical manufacturing processes, enhancing overall production reliability.

- Recommendation and Decision Support Systems: AI systems provide real-time, data-driven recommendations to automotive manufacturing managers, enhancing decision-making processes. By analyzing production data, market trends, and supply chain dynamics, AI supports strategic decisions on production scheduling, resource allocation, and process improvements, leading to greater operational efficiency and effectiveness.

|AI Maturity Levels

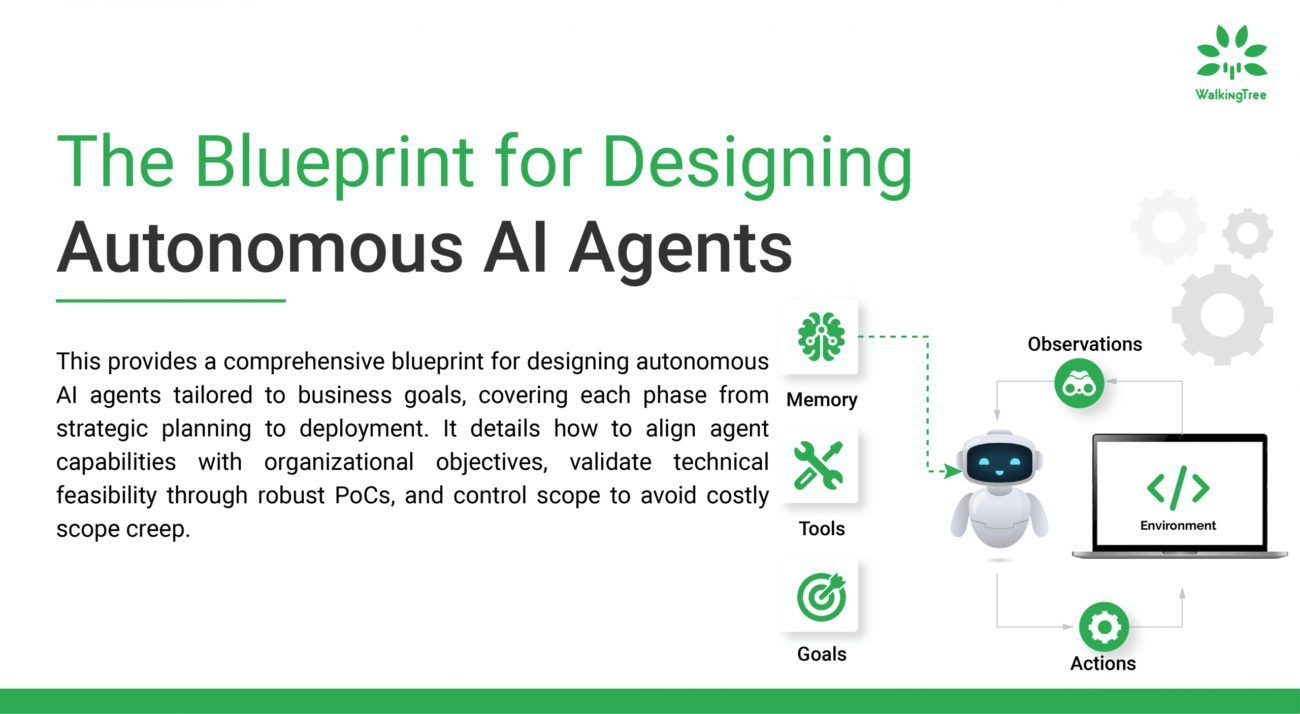

AI’s maturity in manufacturing is categorized into five levels based on human-AI interaction: Humans in Control, AI Assistance, AI Recommendation, Collaborative AI, and AI in Control. These levels represent the evolving autonomy of AI systems, from assisting human operators to fully autonomous decision-making capabilities:

AI solutions in manufacturing have varying levels of maturity, categorized by the autonomy in Human-AI interaction:

- Humans in Control: AI assists but human decision-making is primary.

- AI Assistance: AI provides significant input but requires human validation.

- AI Recommendation: AI suggests actions that humans can choose to follow.

- Collaborative AI: AI and humans work together with shared control.

- AI in Control: AI autonomously makes decisions with minimal human intervention.

These levels reflect the progression of AI integration from assisting human operators to fully autonomous operations.

|Use Cases for AI in Manufacturing

It comes as no surprise that manufacturers are increasingly acknowledging the crucial role of AI in their transition to Industry 4.0, enabling the development of highly efficient, interconnected, and intelligent manufacturing operations.

The potential applications of AI in manufacturing are vast; here are some of the most compelling use cases:

|AI at the Process Level

AI’s integration at the process level revolutionizes quality monitoring, predictive maintenance, and process optimization. Cyber-Physical Systems (CPS) leverage AI to manage quality in real time by analyzing sensor data, which is critical in applications like laser welding.

Intelligent Quality Monitoring & Control

AI plays a crucial role in quality monitoring and control within manufacturing processes. Cyber-Physical Systems (CPS) integrate AI to manage quality in real time, utilizing sensors to collect data and AI algorithms to analyze it. For example, in laser welding, AI combines data from thermal images to monitor the quality of welds, identifying defects and ensuring high standards.

Tool Wear Assessment & Prediction

Monitoring and predicting tool wear is vital for maintaining product quality. AI-driven systems use sensors like accelerometers and inductive clamps to indirectly assess tool wear. By analyzing data patterns, AI can predict when tools need maintenance, preventing breakdowns and ensuring continuous production.

Smart Modelling & Digital Twins

Digital twins, virtual replicas of physical systems, are enhanced by AI to simulate and optimize manufacturing processes. AI accelerates process modeling, enabling near-real-time decision-making and optimization. For instance, AI can manage the workflow of multiple models, ensuring seamless integration and accurate process control.

Process Optimization

AI employs meta-heuristic algorithms like genetic algorithms and particle swarm optimization to refine process parameters in chemical manufacturing. By analyzing vast datasets, AI identifies optimal combinations for cost, quality, and energy consumption, improving overall process efficiency and output quality.

Utilization of Data in Process Design and Operation

Generative models, a subset of AI, are used for data augmentation and synthetic data generation. These models help design products and materials by creating data that mimic real-world conditions. In quality inspection, AI generates synthetic images to train models, improving defect detection accuracy.

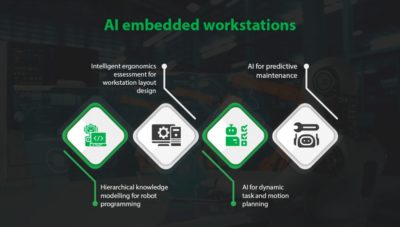

|AI at the Workstation Level

At the workstation level, AI simplifies robot programming through semantic models, transforming high-level commands into precise robot actions. Ergonomics are enhanced by AI assessments that optimize workstation layouts for better worker comfort and productivity.

Hierarchical Knowledge Modelling for Robot Programming

AI simplifies robot programming through hierarchical knowledge modeling, representing humans, robots, and tasks semantically. In an automotive assembly line, task-oriented programming translates high-level commands into specific robot actions. This reduces programming complexity and increases flexibility, allowing for quicker adaptation to new tasks and reducing downtime during reconfiguration.

Intelligent Ergonomics Assessment for Workstation Layout Design

AI systems analyze human movements and interactions with equipment to optimize workstation layouts. In manufacturing, AI assesses ergonomic factors such as reachability and posture, suggesting adjustments to minimize worker fatigue and injury. This results in improved worker comfort, enhanced productivity, and reduced long-term health risks.

AI for Dynamic Task and Motion Planning

AI enhances dynamic task planning by continuously adapting robot motions in response to human presence. In warehouse management, AI ensures safe and efficient interactions between robots and human operators. For instance, robots can dynamically adjust their paths to avoid collisions, maintaining productivity and safety in a collaborative environment.

AI for Predictive Maintenance

AI-driven predictive maintenance systems monitor equipment health and predict failures before they occur. By analyzing sensor data and identifying patterns, AI helps schedule maintenance activities, reducing downtime and extending equipment life.

|AI at the System Level

Now, we turn our attention to the system level, where AI technologies integrate machines, logistics, and software to enhance complex manufacturing environments. Here, we present use cases that illustrate AI’s role in driving efficiency and innovation across system-level operations:

AI-Driven Manufacturing System Design

AI optimizes the design of manufacturing systems by analyzing vast datasets from factory floors, and integrating machines, robots, and logistics in real time. This results in streamlined layouts that improve space utilization and productivity.

Work Management with AI

AI systems manage workforces and resources dynamically, optimizing task assignments, scheduling, and process flows. Real-time adjustments enable manufacturers to respond to shifting demands with precision, reducing bottlenecks and improving overall operational efficiency.

Intelligent Production Planning and Scheduling

AI-powered production planning systems, such as Integrated Process Planning and Scheduling (IPPS), optimize complex manufacturing processes by considering multiple variables—cost, time, and resource availability—to ensure seamless production flows and minimize downtime.

AI-Powered Reporting with Natural Language Processing (NLP)

AI systems generate detailed industrial reports using NLP to interpret and analyze production data. These reports provide actionable insights, enabling decision-makers to quickly understand production issues, trends, and opportunities, improving overall management and strategy execution.

|AI’s Multifaceted Role in Manufacturing

AI’s cross-cutting aspects in manufacturing encompass knowledge representation, robust platforms, data spaces, digital twins, education, ethics, and regulatory frameworks. Knowledge representation models support decision-making, integrating diverse production systems seamlessly.

Knowledge Representation and Semantics

AI leverages semantic models to integrate various production systems in smart factories. These models provide a unified framework for representing knowledge, enabling smooth coordination and interaction between different manufacturing processes. This integration supports real-time decision-making and enhances overall operational efficiency by ensuring all systems work seamlessly together.

Platforms and Infrastructure for AI-based Decision-Making

Developing powerful AI platforms and infrastructure is critical for manufacturing, where computational power and data management are paramount. These platforms support complex AI applications, such as aerodynamic simulations and structural analysis, by providing the necessary computational resources and efficient data-handling capabilities.

Data Spaces for AI Development and Deployment

AI development in the automotive industry relies on access to high-quality datasets. Data spaces facilitate the sharing and management of data from different manufacturers, suppliers, and research institutions. This collaborative approach enables AI models to learn from diverse and extensive datasets, enhancing their performance and applicability in real-world scenarios.

Digital Twins for Synthetic Data Generation

Digital twins use AI to generate synthetic data, simulating various manufacturing scenarios. This synthetic data is used to train AI models, improving their accuracy and reliability. By simulating different conditions and outcomes, digital twins help optimize manufacturing processes and reduce the need for physical trials.

Education and Training Aspects

To adopt AI in industrial automation, companies implement comprehensive education and training programs. These programs equip employees with the necessary skills to operate and maintain AI technologies. Training includes hands-on workshops, online courses, and certification programs focused on AI applications in manufacturing.

Ethical Use and Explainability of AI

Ensuring AI systems are transparent and explainable is critical in consumer product manufacturing. AI models used for quality control and predictive maintenance are designed to be interpretable, allowing stakeholders to understand the decision-making process. This transparency builds trust and ensures the ethical use of AI technologies.

Regulatory Framework for AI in Manufacturing

A reliable regulatory framework guides the development and deployment of AI in pharmaceutical manufacturing. Regulations ensure AI systems are safe, reliable, and compliant with industry standards. This framework covers aspects such as data privacy, algorithmic transparency, and safety protocols, ensuring the responsible use of AI in the production of pharmaceuticals.

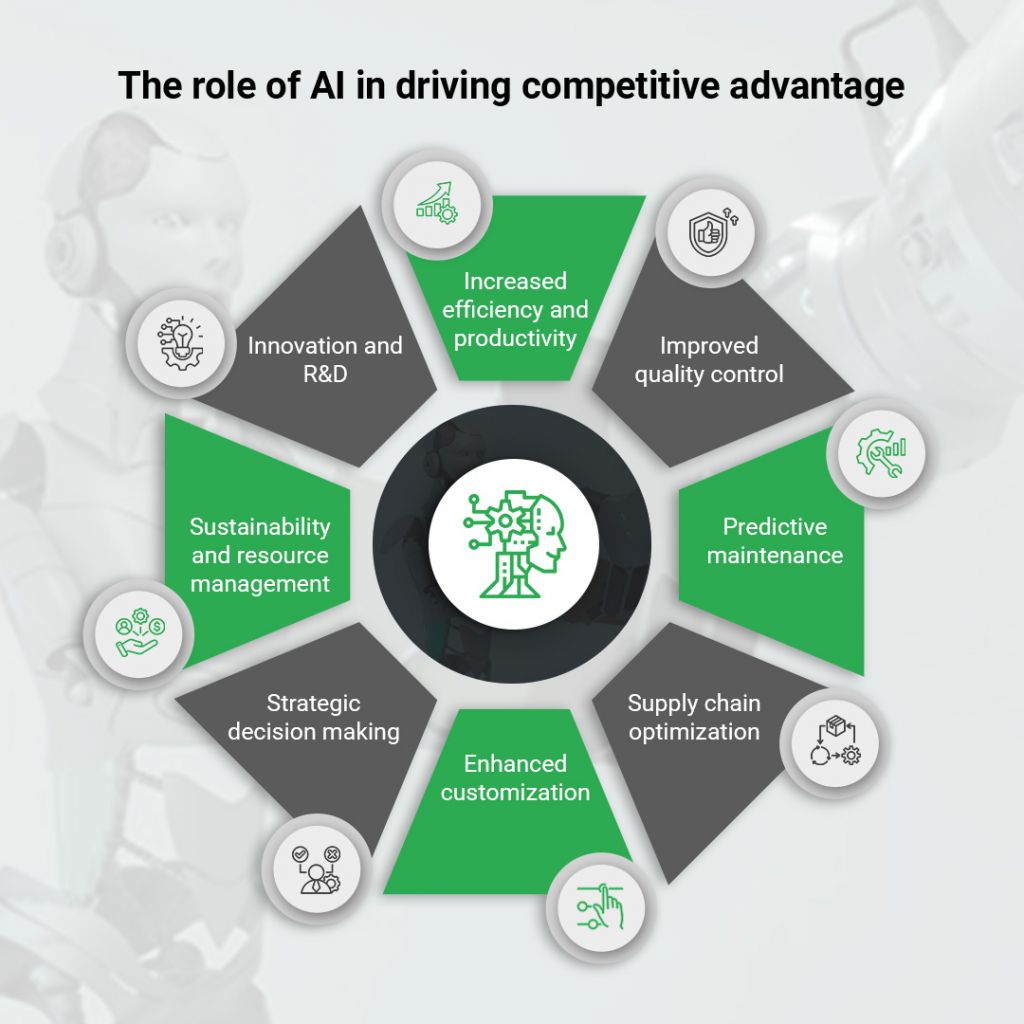

|Potential of AI to Enhance Competitiveness and Technological Leadership

AI has the potential to enhance the competitiveness and technological leadership of manufacturing companies significantly. Here are some key ways AI contributes to these goals:

- Increased Efficiency and Productivity: AI algorithms monitor and analyze real-time data from assembly lines, identifying bottlenecks and optimizing workflows. Automated robotic arms equipped with AI can handle repetitive tasks with high precision, reducing human error and significantly increasing production speed. This leads to higher output and lower operational costs as the system dynamically adjusts to maintain optimal performance levels.

- Improved Quality Control: AI-powered vision systems inspect machine components during production, detecting defects such as scratches, dents, or misalignments with high accuracy. By integrating deep learning models, the system continually improves its detection capabilities, ensuring that only flawless products reach the market. This process minimizes waste and enhances customer satisfaction by maintaining consistent product quality.

- Predictive Maintenance: AI models analyze data from sensors embedded in semiconductor manufacturing equipment to predict potential failures. By identifying patterns indicative of wear and tear, AI schedules maintenance before critical failures occur, reducing unplanned downtime and extending the equipment’s lifespan. This ensures smooth, continuous operations and reduces overall maintenance costs.

- Supply Chain Optimization: AI algorithms forecast demand and manage inventory for consumer goods manufacturers. By analyzing market trends, sales data, and external factors, AI identifies potential supply chain bottlenecks and optimizes logistics. This enhances supply chain efficiency, enabling manufacturers to surpass industry benchmarks and establish a formidable market position.

- Enhanced Customization: Machine learning models analyze customer preferences and feedback to customize product designs at scale. AI adjusts production parameters to cater to individual customer requirements, such as size, style, and color preferences.

- Strategic Decision Making: AI systems aggregate and analyze vast amounts of market data, consumer behavior, and sales performance for companies. By providing actionable insights, AI helps executives understand market trends and make informed decisions on product launches, marketing strategies, and resource allocation, leading to more effective and strategic decision-making.

- Sustainability and Resource Management: AI models monitor energy consumption across chemical manufacturing plants, identifying inefficiencies and suggesting optimization strategies. By implementing AI-driven recommendations, manufacturers can reduce energy usage, minimize waste, and lower their environmental impact. This contributes to sustainable manufacturing practices and improves overall operational efficiency.

- Innovation and R&D: AI accelerates research and development in companies by analyzing data from previous experiments and suggesting new compounds and testing methodologies. Keeping manufacturers at the forefront of technological advancements and ensuring a competitive edge in the industry.

|Conclusion

AI is transforming the manufacturing industry by enhancing efficiency, quality, and flexibility. Integrating AI technologies at various levels of manufacturing processes and workstations is driving significant improvements in productivity and competitiveness. As AI continues to evolve, its role in manufacturing will become even more critical, paving the way for autonomous and intelligent factories of the future. By adopting AI technologies, manufacturers can enhance their competitiveness, drive technological innovation, and achieve greater efficiency and sustainability. The future of manufacturing lies in the intelligent and strategic use of AI, making it an essential component for any company aiming to lead in the digital environment.

At WalkingTree Technologies, we specialize in integrating advanced AI solutions to revolutionize your manufacturing operations. Our expertise in machine vision, predictive maintenance, digital twins, and more can help you achieve unparalleled efficiency, precision, and innovation.

Visit our website to discover how we can enhance your manufacturing capabilities and drive your business forward in the digital system.

Stay tuned for the next blog in the series.

References: