Blogs

TechOps and Digital Transformation in Aerospace: Advancing with Digital Twins and FMEA Builders

Atlanta, a prominent aerospace sector hub, is undergoing a substantial shift due to technology discoveries. The aerospace sector in Atlanta alone contributes over $3 billion annually to the economy, employing more than 27,000 professionals. Considering its significant economic impact, technical operations (TechOps) now heavily rely on the integration of the latest technologies. TechOps, the backbone of aerospace maintenance and operational efficiency, is now embracing digital innovations to enhance performance, reduce downtime, and ensure safety. In this blog, we’ll delve deeper into learning how the aerospace industry in Atlanta can benefit from integrating Digital Twins and FMEA Builders.

|Emerging Trends in Aerospace TechOps

Key trends in the aerospace industry include the adoption of IoT, AI, machine learning, advanced analytics, and other digital transformations. Let’s have a look at them in detail:

- Predictive Maintenance: Leveraging data analytics to anticipate and prevent equipment failures. Predictive maintenance can reduce maintenance costs by up to 30% and unplanned downtime by 45%.

- IoT Integration: Utilizing IoT devices for real-time monitoring of aircraft systems. The global IoT in the aerospace and defense market is expected to reach $40 billion by 2025.

- AI and Machine Learning: Enhancing decision-making processes through AI-driven insights. AI in aviation maintenance is projected to grow at a CAGR of 46.4% from 2020 to 2027.

- Digital Twins: Creating virtual replicas of physical systems to simulate and analyze performance. The digital twin market in aerospace and defense is estimated to grow from $1.1 billion in 2020 to $4.5 billion by 2025.

Atlanta’s aerospace industry is at the forefront of these trends, with major players investing heavily in digital transformation initiatives. The goal is to enhance operational efficiency, reduce costs, and improve safety standards.

Do you know how Digital Twins and FMEA Builders help in the Aerospace Industry?

Aerospace firms still have a lot of work to do to ensure safety and maintain operating efficiency, even with breakthroughs. Conventional maintenance techniques are frequently reactive, which raises operating costs and causes unplanned downtime. Modern aircraft systems are complicated, necessitating more accurate and proactive maintenance and operations.

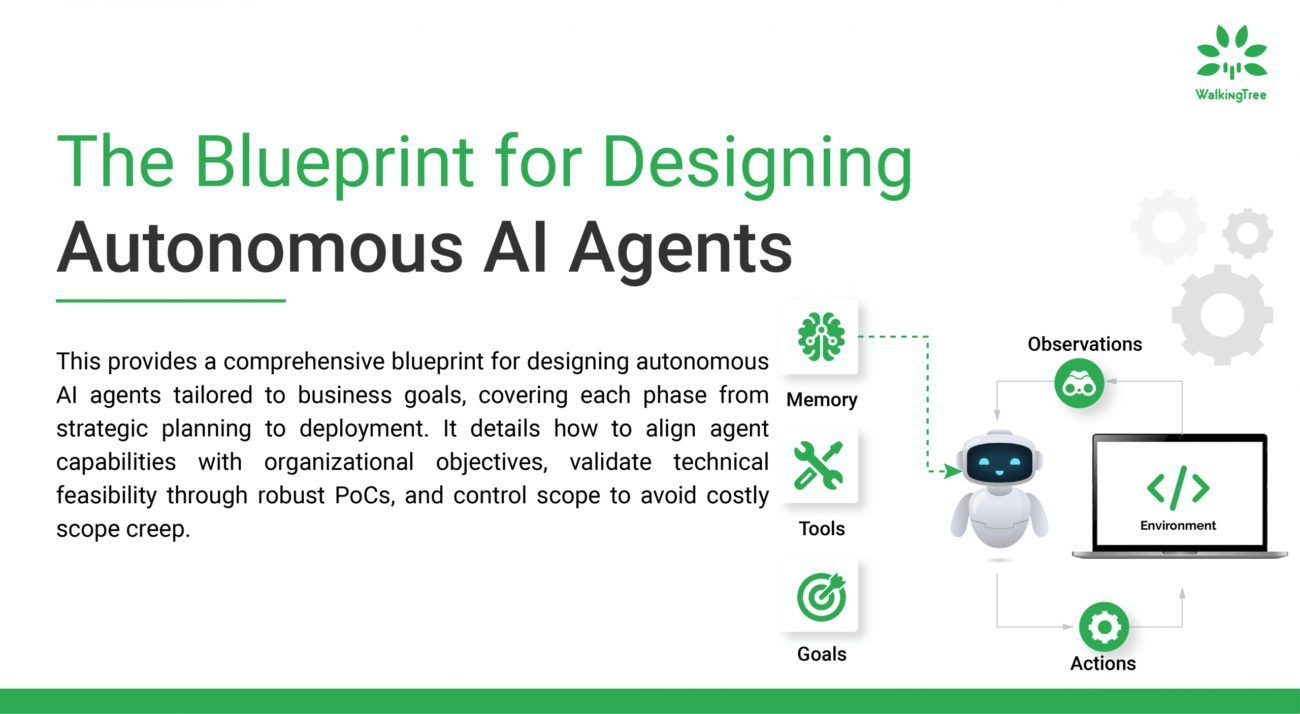

Comprehensive answers to these problems are provided by Failure Mode and Effects Analysis (FMEA) builders and digital twins. Digital Twins allow for real-time aviation system monitoring, modeling, and analysis by generating virtual copies of actual assets. Proactive risk management is made possible by the methodical identification of probable failure modes and their consequences by FMEA builders.

The aerospace sector is known for pushing limits all the time, and digital twins play a major role in encouraging good progress by improving efficiency and safety.

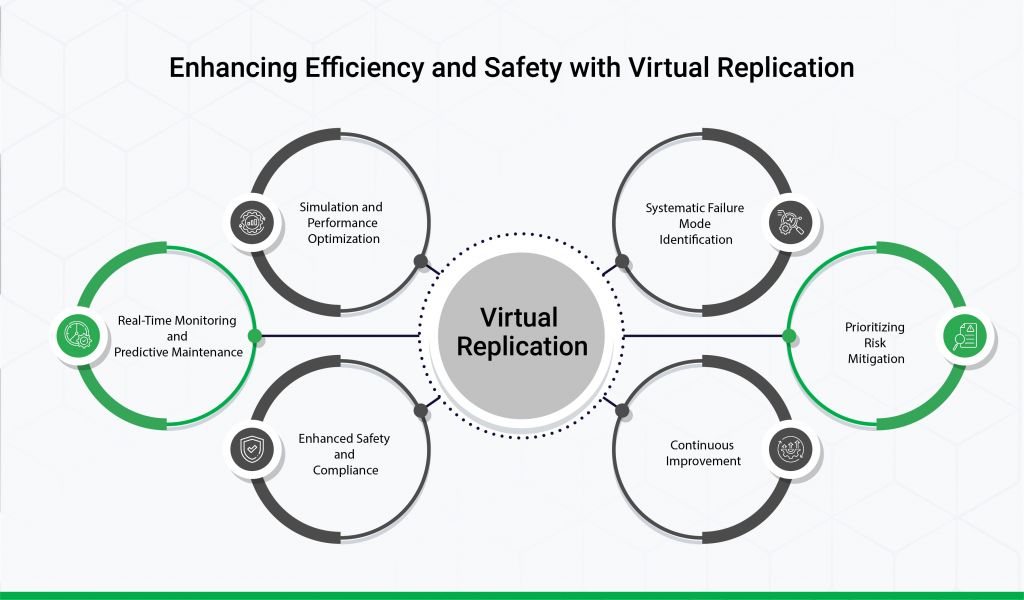

|Here’s how Virtual Replication can help:

|Real-Time Monitoring and Predictive Maintenance

Digital Twins provide a real-time, digital counterpart of physical assets, enabling continuous monitoring and analysis. This real-time data allows for predictive maintenance, identifying potential issues before they become critical, thus reducing downtime and maintenance costs.

|Simulation and Performance Optimization

Digital Twins enable the simulation of various operational scenarios, providing valuable insights into system performance under different conditions. This capability is crucial for optimizing performance, testing new strategies, and making informed decisions without the risks associated with physical trials.

|Enhanced Safety and Compliance

By simulating potential failure scenarios, Digital Twins helps identify and mitigate risks, ensuring compliance with safety regulations. This proactive approach significantly enhances the overall safety and reliability of aerospace operations.

|Systematic Failure Mode Identification

FMEA builders systematically analyze aircraft systems to identify potential failure modes and their effects. This structured approach helps in understanding the root causes of failures and implementing effective preventive measures.

|Prioritizing Risk Mitigation

By assessing the severity, occurrence, and detectability of potential failures, FMEA builders prioritize risk mitigation efforts. This ensures that the most critical risks are addressed first, enhancing the overall reliability of aerospace systems.

|Continuous Improvement

FMEA builders support continuous improvement by providing a framework for regular review and updating of risk assessments. This iterative process ensures that risk management strategies remain effective and up-to-date with evolving system complexities.

|Enhancing Aerospace Operations with Digital Twin and TechOps Solutions

WalkingTree Technologies introduces a powerful analytics platform designed to unlock manufacturing excellence through advanced factory automation solutions. This platform enables aerospace companies to enhance decision-making by utilizing advanced data analytics to gain deeper insights into operations. Additionally, it improves operational efficiency by leveraging real-time data to streamline processes and boost predictive maintenance to foresee potential issues and mitigate risks before they escalate.

-

Digital Twin Technology: Operation Monitoring and Optimization

The platform’s capabilities in Digital Twin technology allow aerospace companies to create virtual replicas of manufacturing assets. By combining real-time data and virtual models, companies can monitor machine performance, identify bottlenecks, and optimize processes. This comprehensive view of factory operations enables data-driven decisions, reduces inefficiencies, and enhances overall operational performance.

-

FMEA Builders: Proactive Risk Management

In addition, the platform offers FMEA (Failure Modes and Effects Analysis) Builder for proactive risk management. It simplifies the assessment of potential failure modes within manufacturing operations, identifies critical failure points, and prioritizes mitigation strategies. This proactive approach helps prevent downtime, ensures the highest quality standards in production, and maintains customer satisfaction.

-

Real-Time Insights and Streamlined Data Management

Real-time dashboarding and predictive maintenance features provide aerospace companies with real-time insights into factory performance. These tools enable companies to track production efficiency, monitor equipment utilization, and predict potential equipment failures. The document ingestion capability streamlines data management by automating the capture and digitization of critical manufacturing documents, ensuring compliance with industry regulations and enhancing collaboration.

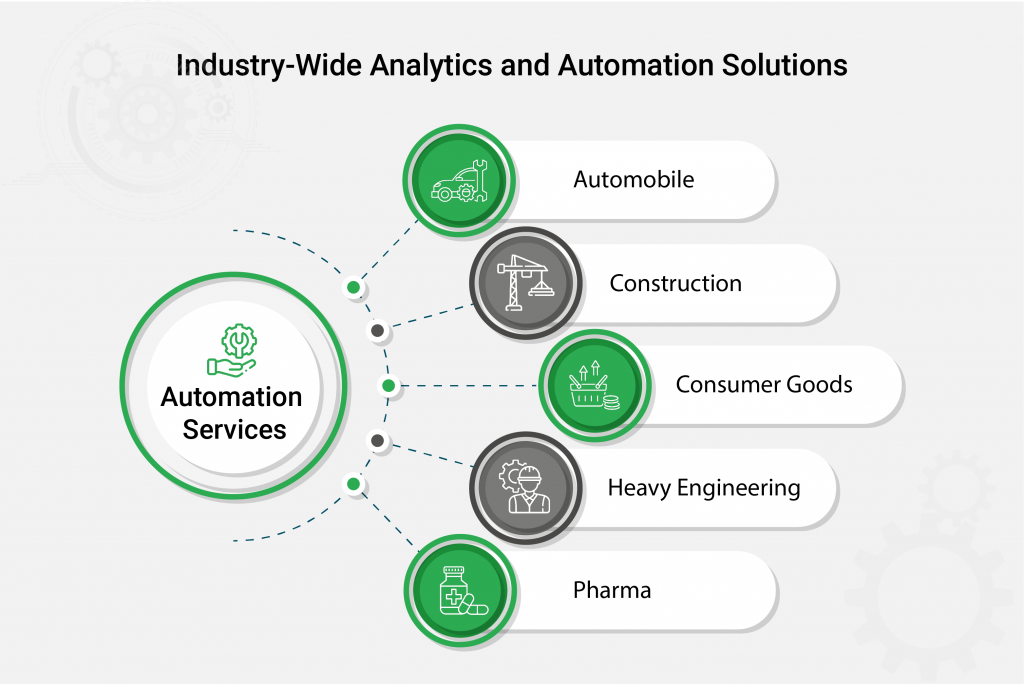

|Analytics and Automation Solutions Across Manufacturing Industries

Unlock manufacturing excellence across industries with powerful factory automation solutions:

- Automobile: Improve production efficiency, optimize supply chain, and enhance product quality with Factoid’s real-time insights and predictive analytics.

- Construction: Enhance project management, track resource utilization, and ensure compliance with Factoid’s document ingestion and real-time dashboarding features.

- Consumer Goods: Optimize manufacturing processes, improve product reliability, and drive innovation with Factoid’s comprehensive view of factory operations and digital twin technology.

- Heavy Engineering: Streamline equipment maintenance, minimize downtime, and maximize productivity through Factoid’s predictive maintenance and failure analysis capabilities.

- Pharma: Ensure regulatory compliance, enhance quality control, and streamline data management with Factoid’s document ingestion, traceability, and compliance features tailored for the pharmaceutical sector.

|Industries in which Digital Twins can be an asset

While we’re focusing on the aerospace industry, it’s worth noting that Digital Twins and FMEA builders offer significant value across various sectors, including retail. In the retail industry, Digital Twins can transform operations by providing real-time insights into supply chain management, inventory optimization, and customer behavior analysis. Here are some operational changes that Digital Twins can help with:

- Supply Chain Visibility: Digital Twins provide end-to-end visibility into supply chain operations, enabling real-time monitoring and optimization.

- Inventory Management: By simulating various inventory scenarios, Digital Twins help optimize stock levels, reducing excess inventory and stockouts.

- Customer Experience: Digital Twins enable retailers to analyze customer behavior and preferences, enhancing personalized shopping experiences and increasing customer satisfaction.

- Operational Efficiency: Real-time data and predictive analytics help identify and address operational inefficiencies, driving cost savings and improving overall performance.

|The Integration of Digital Twins and FMEA Builder

The integration of Digital Twins and FMEA builders in aerospace TechOps marks a significant leap toward enhanced operational efficiency, safety, and cost-effectiveness. As the aerospace industry in Atlanta continues to evolve, these advanced technologies will play a crucial role in shaping the future of aerospace operations.

WalkingTree Technologies, with its expertise in Digital Twin development and FMEA solutions, is well-positioned to lead this transformation. By offering tailored, innovative solutions, WalkingTree empowers aerospace companies to overcome their most pressing challenges and achieve operational excellence.

Visit our website to learn more about our solutions and expertise.